The Asphalt Mix Database allows you to create, price and save mutiple asphalt mix designs. Within this database you can enter plant, aggregate, and liquid costs to generate a complete mix design cost. You can then load a mix into an estimate and generate reports showing raw material requirements and total mix requirements. \There are two types of asphalt databases within the system: Master Materials Database and Project Materials Database. The Master Database should contain all of the mixes currently available for use in an estimate. Once a mix has been loaded into an estimate, that mix is copied to the Project Materials Database and you can edit the mix for that project, if desired.

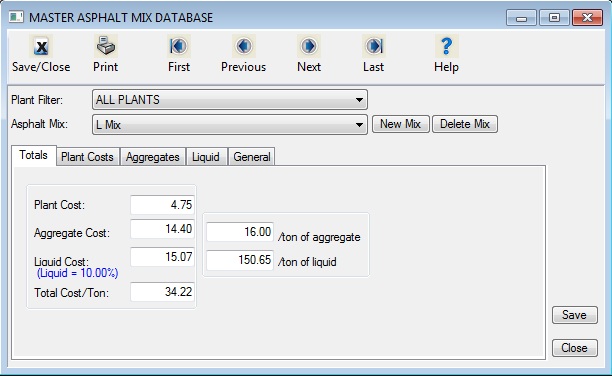

Figure 1 shows the first screen within the database. Each of the options on this screen is explained below.

Figure 1

|

Plant Filter

|

This dropdown box you to select the desired asphalt plant.

|

|

Asphalt Mix

|

This dropdown box allows you to see and select from a list of mix designs available at the selected plant, create a new mix, or delete an existing mix design.

|

|

Totals Tab

|

(READ ONLY)This tab shows a breakdown of the costs associated with the currently selected Mix design.

|

|

Plant Cost

|

(READ ONLY) This field displays the total plant cost for the selected mix at the selected plant.

|

|

Aggregate Cost

|

(READ ONLY) This field displays the total aggregate cost for the displayed mix.

|

|

Liquid Cost

|

(READ ONLY) This field displays the total liquid cost for the displayed mix.

|

|

Total Cost/Ton

|

(READ ONLY) This field displays the total mix cost for the displayed mix. The mix cost is calculated using the following formula:

|

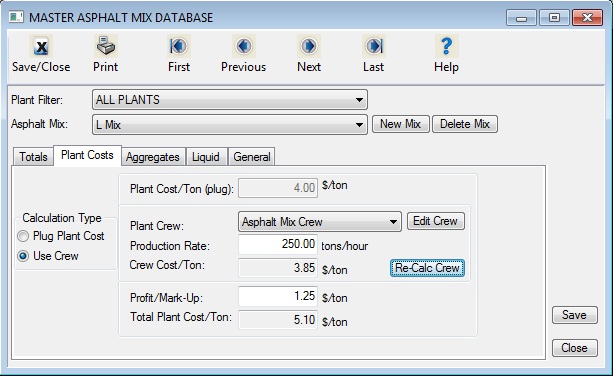

The first step in creating a mix design price is to enter the plant costs. Figure 2 shows the screen where you enter the plant cost data. The first decision to make is whether you want to enter the plant costs as a plug cost per ton OR set up a plant crew and enter a plant production rate and have the system calculate the plant cost per ton.

Figure 2

|

Plant Cost/Ton (plug):

|

This field allows you to enter a plug cost per ton. This field is only available if you select the “Plug Plant Cost”

|

|

Calculation Type

|

These options allow you to select how to enter the plant cost. If you select “Plug Plant Cost,” you will only be able to enter costs into Plant Cost/Ton (plug). If you select “Use Crew” you must select the Plant Crew, the Production Rate, and a Profit/Mark-Up.

|

|

Plant Crew

|

This list box allows you to select a crew from the Crew Database. Within the Crew Database, you can set up a plant crew which includes all of the plant equipment, support equipment, operators, and support labor. The system will then calculate an hourly cost and divide that cost by the production rate to arrive at a plant cost per ton. NOTE: The crew in the crew library must be assigned to the “Asphalt Mix Design” category.

|

|

Production Rate

|

This field is used to enter the average plant production rate per hour. The production rate should be an “average” production rate and should include an historic downtime rate for that plant.

|

|

Crew Cost/Ton

|

(READ ONLY) This field displays the total crew cost per ton. The total hourly crew cost is calculated and then divided by the hourly production rate to arrive at the cost per ton.

|

|

Profit/Mark-Up

|

This field is used to enter the plant mark-up or profit per ton. This amount is added to the plant cost.

|

|

Total Plant Cost/Ton

|

(READ ONLY) This field displays the total plant cost per ton. Depending on which method you chose, this cost will be either the Plug Cost plus the mark-up OR the Crew cost per ton plus the mark-up. This total will also be displayed on the Totals Screen (2).

|

The second step in creating a mix design price is to enter the aggregates that will be used in the mix. Figure 3 shows the screen where you enter the aggregate cost data. Note: the aggregate percentage should add up to 100. The system will automatically adjust these totals based on the liquid percentages entered in the next section.

Figure 3

|

Aggregates Tab

|

This screen is displayed by selecting the “Aggregates” tab on the Mix Design Screen.

|

|

Code/Description

|

The first two columns display the material code and description. The code and description are saved in the Material Database. NOTE: The system will only allow you to select material items that are in the “AS” category in the Material Database.

|

|

Percent

|

This field displays the percentage that each item makes up of the total aggregates. Remember, the total of all aggregates should be 100%.

|

|

Waste

|

This field displays the waste percentage for each aggregate. The waste can include such items as moisture loss and/or stockpile waste.

|

|

Price

|

This field displays the cost per ton of each aggregate. When loading a new aggregate, the system will initially load the default unit price saved in the Material Database. You can change this cost at any time. Also, once a mix is loaded into an estimate, you can change the aggregate and liquid costs within the estimate without changing the mix cost in the Master Database.

|

|

Haul

|

This field displays the cost of hauling each aggregate to the Asphalt Plant (not to the Project site). When loading a new aggregate, the system will initially load the default hauling price saved in the Material Database. You can change this cost at any time.

|

|

T

|

This field indicates whether or not an item is taxable. You can turn the Tax additive on and off by selecting the Edit button. |

|

Tax Rate

|

This field displays the sales tax rate for the current item. If an item is taxable and the tax rate is set to zero, then the system will use the default sales tax rate. This option allows you to use different sales tax rates for individual items (if they are purchased in different locations with different rates).

|

|

Add

|

Press this button to add a new aggregate to the list. You will then be prompted to select the material item to add. Figure 4 |

|

|

|

|

|

|

|

Edit

|

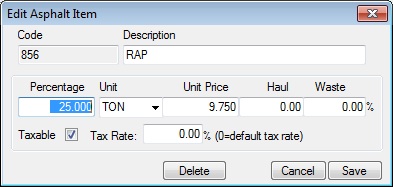

Press this button to edit the currently highlighted aggregate item. You can also double click on an item to display the edit window. From the Edit Asphalt Item window (Figure 5, above) you can change the percentage, cost, hauling cost, waste, or taxable status.

|

| Delete |

Press this button to delete the currently highlighted aggregate item.

|

|

Totals/Percentage

|

(READ ONLY) This field displays the total of all the aggregate percentages. The total of all the aggregates should add up to 100%. The system will automatically adjust the prices based on the liquid asphalt percentage.

|

|

Totals/Cost

|

(READ ONLY) This field displays the total aggregate cost (Per Ton of Aggregate) including hauling, waste, and tax. |

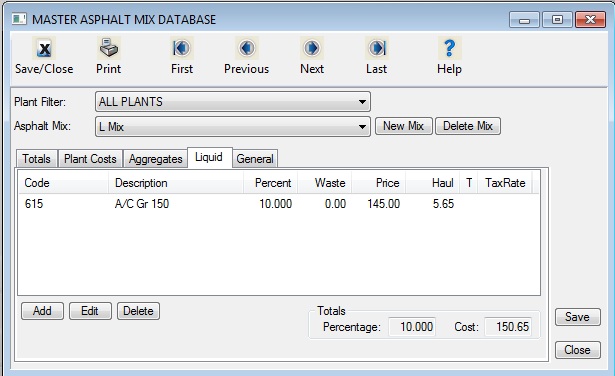

The third step in creating a mix design price is to enter the liquid asphalt type to be used in the mix. Figure 6 shows the screen where you enter the liquid cost data. Note that the percentage of liquid is entered as the percent of mix by weight (typically in the 4%-8% range). You can enter as many liquid items as needed, but most cases there will only be one liquid item. This screen operates just like the aggregate screen, and the data required is the same.

Figure 6

|

Liquid Tab

|

This screen is displayed by selecting the “Liquid” tab on the mix design screen. |

|

Code/Description

|

The first two columns display the material code and description. The code and description are established and saved in the Material Database. NOTE: The system will only allow you to select material items in the “AS” (“Asphalt Mix Design”) category.

|

|

Percent

|

This field displays the percentage (of the total mix) for each individual liquid item. |

|

Waste

|

This field displays the waste percentage for each liquid item. |

|

Price

|

This field displays the cost per ton of each item. When loading a new liquid item, the system will initially load the default unit price saved in the Material Database. You can change this cost at any time. Also, once a mix is loaded into an estimate, you can change the aggregate and liquid costs within the estimate without changing the mix cost in the Master Database.

|

|

Haul

|

This field displays the hauling cost of each item. When loading a new item, the system will initially load the default hauling price saved in the Material Database. You can change this cost at any time. Also, once a mix is loaded into an estimate, you can change the aggregate and liquid costs within the estimate without changing the mix cost in the Master Database.

|

|

T

|

This field indicates whether or not an item is taxable. |

|

Tax Rate

|

This field displays the sales tax rate for the current item. If an item is taxable and the tax rate is set to zero, then the system will use the default sales tax rate. This option allows you to use different sales tax rates for individual items (if they are purchased in locations with different rates).

|

|

Add

|

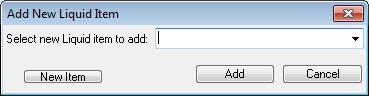

Press this button to add a new liquid item to the list. You will first be prompted to select the material item to add, Figure 7.

|

|

|

|

|

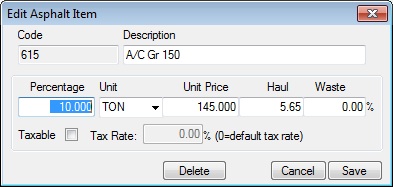

NOTE: The system will only allow you to select a material item in the “AS” (“Asphalt Design Mix”) category. After selecting the item, you will then be prompted to enter the remaining information as shown in Figure 8.

|

|

|

|

|

|

Edit

|

Press this button to edit the currently highlighted item. You can also double click on an item to display the edit window. From the edit window you can change the percentage, cost, hauling cost, waste, or taxable status. |

|

Delete

|

Press this button to delete the currently highlighted item. |

|

Totals/Percentage

|

(READ ONLY) This field displays the total of all the liquid percentages. |

|

Totals/Cost

|

(READ ONLY) This field displays the total liquid cost (Per Ton of Liquid) including hauling, waste, and tax. |

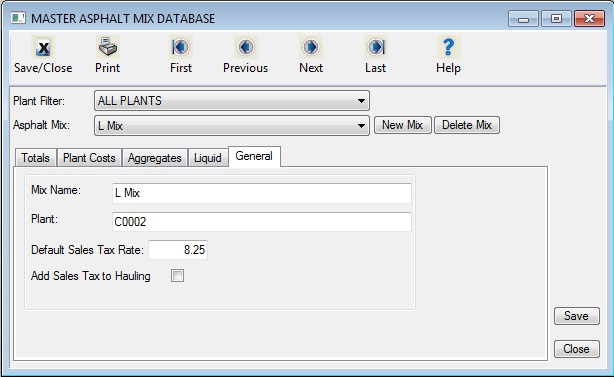

The last step in creating a mix design price is to enter the general information about the new mix design. Figure 9 shows the screen where you enter this information.

Figure 9

|

General

|

This screen is displayed by selecting the “General” tab on the mix design screen. |

|

Mix Name

|

This field allows you to change the name or description of the mix. |

|

Plant

|

This field is used to enter a plant code or name. Some of the reports allow you sort the mixes by plant.

|

|

Default Sales Tax Rate

|

This field is used to enter the sales tax rate to be used as a default. As mentioned earlier, you have the ability to over ride the default sales tax rate on individual aggregate and/or liquid items.

|

|

Add Sales Tax to Hauling

|

This field is used to determine whether or not to add sales tax to the hauling cost for aggregate or liquid items.

|

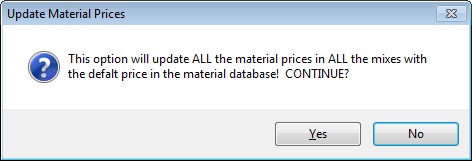

Material prices for asphalt aggregate can be update from 2 loacations. (1) in the aggregates tab in a mix design select the "Update Materials Prices" button or (2) The Edit menu option(at the top of the main estimate level). All the material prices (both aggregate and liquid prices) for all mixes in the asphalt database will be updated to the current material prices in the material database.

Answer YES to this prompt to replace all the prices.

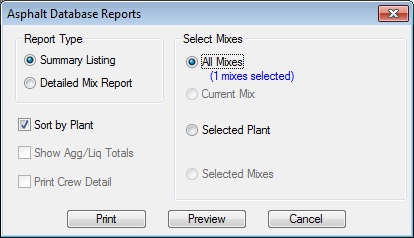

You can print two types of reports: Summary Listing or Detailed Mix. The Summary Listing is a list of all the mixes in the database showing the description and the aggregate, liquid, and total cost of each mix. The detailed report prints a one-page report for each selected mix showing all of the detail that makes up the cost. Figure 11 shows the report options screen. A sample asphalt mix report is shown in Figure 12.

Figure 11

|

Report Type

|

You can print two types of reports: Summary Listing or Detailed Mix. The Summary Listing is a list of all the mixes in the database showing the description and the aggregate, liquid, and total cost of each mix. The Detailed Mix Report prints a one-page report for each selected mix showing all of the detail that makes up the cost.

|

|

Sort By Plant

|

This check box allows you to sort the report based on plant code; otherwise, the report will be sorted on the mix code. This option is only available for the Summary Listing.

|

|

Select Mixes

|

Using this button you can select which mixes to print. This option is only available for the Detailed Mix Report. After pressing this button a window will be displayed allowing you to select which mixes to print. The number of mixes you selected will be displayed below the button.

|

|

Print/Preview/Cancel

|

These three buttons allow you to print, preview, or cancel the report. You can also print or export the report from the preview screen.

|

|

|

|